Swipe right

2024

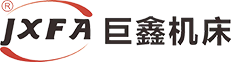

The dual vertical lathe has achieved multifunctionality and multi-modularity, having developed various models that incorporate multiple functions such as turning, milling, and pressing, along with dual positive and negative vertical lathes. This has led to significant breakthroughs, culminating in the invention patent for the saw and punch composite center hole lathe.

2022-2023

The new vertical lathe and long-stroke inverted lathe of the dual-head CNC lathe have been successfully launched.

2021

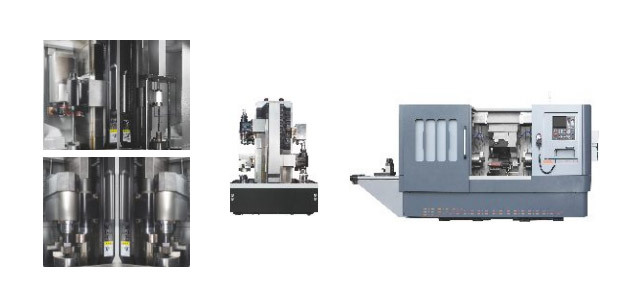

The car-milling composite, multi-model shaft and disc multi-machine combination intelligent production line has successfully gone offline for mass production.

2020

We have embarked on the path of Smart Manufacturing 2025, and the smart production line has successfully produced.

2018-2019

After two years of effort, we have successfully designed a dual-spindle dual-turret CNC vertical lathe and ultra-high-pressure steam cleaning equipment, and have applied for multiple utility model and invention patents (international patents). We have successfully designed various assembly line configurations using joint robots, including one-to-three, one-to-four, one-to-five, and one-to-six machine setups.

2017

The new factory has successfully produced and manufactured intelligent flexible center hole machine tools for Japanese companies, receiving high praise from clients for several international new technologies. Additionally, we have developed intelligent press-fitting equipment, which adds new momentum to refresh press-fitting records in the future big data era (while also entering the Chinese high-speed rail industry).

2016

We have entered a new era of intelligent manufacturing, focusing on precision machine tools and developing our own system software. This allows for the integration of various machine models into an automated production line, making intelligence more aligned with flexible production lines. We have successfully completed the integration of two automated production lines for axle components with FAW Group, achieving fault-free production to date.

2015

Juxin has meticulously crafted a six-axis milling and drilling center for the axle machine, which has been successfully used in production at Siemens. Additionally, it has successfully completed the integration of two automated production lines for axle components with SAIC Group. (This has made it the first domestic and foreign machine tool manufacturer to complete the qualified acceptance in the shortest time among all equipment at SAIC, with stable usage that has changed the perception of domestic machine tools in the automotive industry.)

2014

In the manufacturing industry, value is reflected here; over nine wonderful years, Juxin has won nearly twenty utility model patents, and has been recognized as a high-tech enterprise in Taizhou, as well as receiving the Innovation Enterprise award from the Taizhou Machine Tool Association for the second time.

2012-2013

The market demand is expanding, and new products such as ultra-large flat bed center hole machine tools, high-efficiency spline forming machines, and deep hole drilling machines with slant bed designs are being successively launched into production. The introduction of these new products has been well received by customers, leading Zhengmei Machine's American subsidiary in Hefei to produce large center hole machine tools for Fuzhou Precision Forging, and to manufacture the ultra-large slant bed center hole machine tool for Shanghai Madek Electric, which is the first large slant guide center hole machine tool in the country.

2011

Many well-known domestic and foreign enterprises and companies have established ordering relationships, including Siemens from Germany and SEW from Germany, which specializes in the research and development of multifunctional milling and drilling high-end combined machine tools, as well as the development of small integrated slant bed center hole machines and super large slant bed center hole machines, fully opening the door to high-end customers.

2010

The company team has grown, cultivating a group of experienced talents in research and development, as well as production manufacturing. During bidding, we entered the Yuchai Power production line with leading technological advantages in various functions, and successively completed the development and trial production of large and super-large equipment for companies such as Jianghuai Group and Changan Group (Chongqing/Chengdu Qingshan), which were successfully used by Laigang Group. The small split slant bed center hole machine and large diameter double-headed U drill were successfully used for production trials.

2009

Mid-to-high-end products are favored by the market. The company has signed production contracts for center hole machines with high-end companies such as NSK (Zhejiang Branch), Dongli Group, Guomao Group, and Feiya Crankshaft. (Successfully developed fully automatic slotting machines and small inclined bed center hole machines)

2007-2008

The company has completed the establishment of various departments and has conducted multiple technical upgrades on the center hole machine tools, applying for several national patents for mass production. (Successfully developed a split lightweight center hole machine tool) The major departments of the company are operating normally and have begun to develop mid-to-high-end products; developing new types of center hole machine tools for large motor manufacturers such as Fujian Anbo Group, Zhejiang Jinlong Co., Ltd., and Shanghai Tebao Motor. (Successfully developed an integrated heavy-duty center hole machine tool)

2005-2006

Juxin Company was established and developed the first generation of center hole machine tools, featuring a simple structure, practical design, and extremely high processing efficiency, capable of processing 4 parts in 1 minute, receiving positive feedback from many customers. The construction of the technology research and development center was completed, and a new patent for center hole machine tools was applied for at the national level. (Successfully developed small and medium-sized center hole machine tools)

1988

Second generation of machinery

1958

First generation of machinery