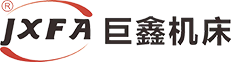

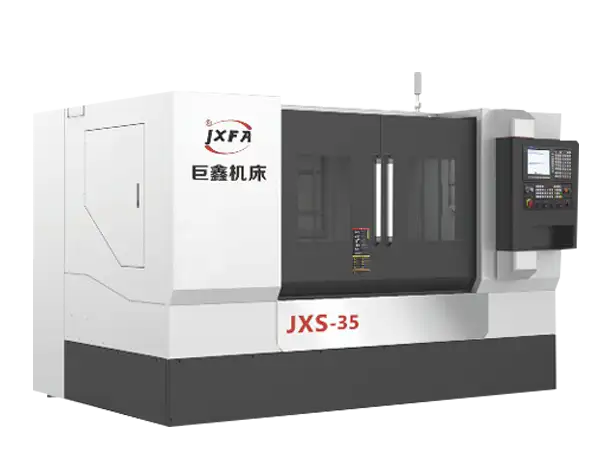

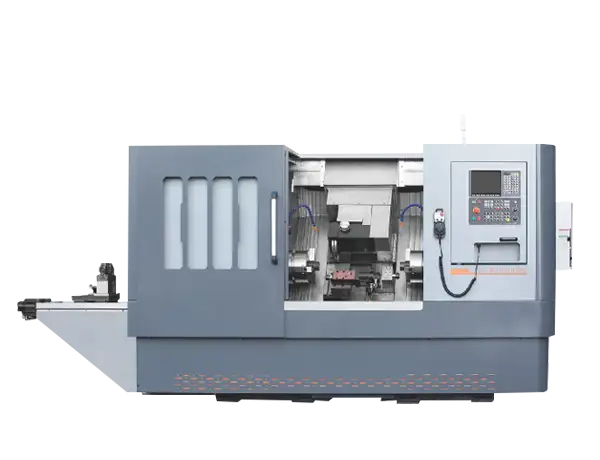

Product Series

Efficient, Safe, Precise, Stable

Starting from the customer - required process, develop and design high - performance machine tools with specific targeting

Emphasis on Innovation

Independent R & D capabilities

High - precision processing equipment

Over 40 utility model patents and over 10 invention patents

Six - unit automated production line with non - interference between humans and articulated robots

01

Small footprint

For processing a 1 - meter motor shaft, the floor area of the vertical lathe production line is 7.5×9.6 meters

For processing a 1 - meter motor shaft, the floor area of the inclined lathe production line is 5×43 meters, resulting in a large waste of workshop space

02

Short manual operation distance

The rigidity is increased by more than 30% compared to conventional standard machine tools, the single - tool cutting amount reaches over 12mm, the processing efficiency is high, and the output is 125% of that of similar machine tools

Conventional standard machine tools have poor rigidity, low cutting amount, and slow processing efficiency

03

Advantages of Automated Connection

Intelligent detection console (optional)

Processing live video

Partners

Highly recognized and used by many top - ten international enterprises

Company establishment time

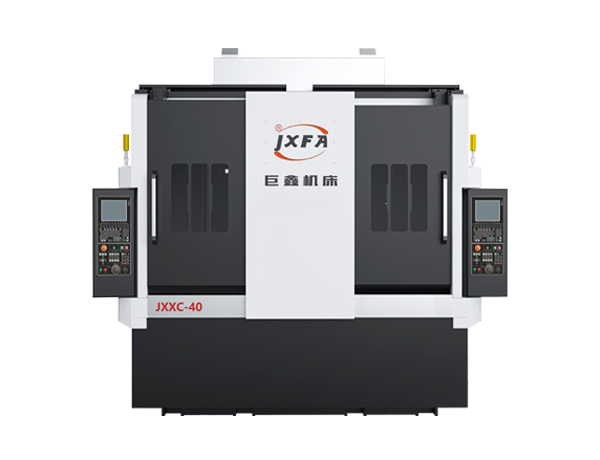

Product Series

Patented technology

Middle and high-end cooperative customers

In 2016, Juxin became a drafting unit of the association group standard for center - hole machine tools and was awarded the "Standard Pilot Enterprise" by the Ministry of Industry and Information Technology.

In 2018, it successfully developed multiple series of double - spindle CNC double - column vertical lathes, which were highly praised by peers and obtained a number of new technical patents.

In 2019, it became the main drafting unit for the national center - hole standard application.

In 2024, it successfully achieved multi - functional, multi - module, integrated production of double - column vertical lathes/double upright and inverted lathes, as well as sawing and drilling composite center - hole lathes.

Bolg